To all news

Cleaning water from petroleum products

28.12.2022

A drop of oil makes 25 liters of water undrinkable. Even in such small quantities, it damages the human heart, blood vessels and nervous system, and threatens fish and aquatic plants with extinction. How can I get rid of petroleum products in my water so that I don't lose my drinking water and keep aquatic life alive? Let's look at the main ways to clean water from petroleum products.

12/28/2022

After that, the content of petroleum products in water must not exceed MPC - the maximum allowable concentration norm, which guarantees that the water is safe for water inhabitants and people. For an enterprise, exceeding MPC in treated water or discharging untreated wastewater into a pond may result in higher environmental charges or fines. Let's take a look at the main ways to clean water from oily contaminants.

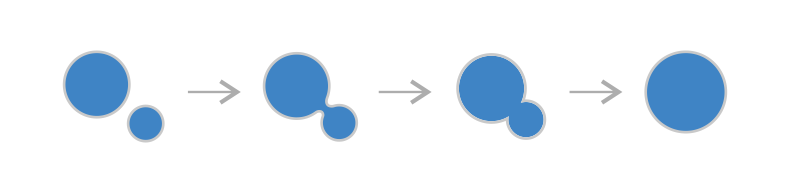

Some oil traps or oil traps have a coalescent filter - several polymeric plates placed close to each other. When runoff flows through them, the polymeric material attracts particles of oil-containing contaminants, where they are combined into droplets. The flow of water vibrates the plates and the droplets detach from them, float to the surface and form a film. This happens if the density of oily contaminants is less than the density of water. If the opposite is true, they settle to the bottom. The resulting film and sludge are collected and transferred for disposal.

Coagulation is supplemented by flocculation. This helps separate water from contaminants faster and form more large, dense flocs which are easier to remove.

This method is used when it is necessary to comply with stringent requirements for discharging effluents into water bodies, and other treatment methods do not give the desired result. For example, in the case of oily contaminants, water is sent for sorption filtration for further treatment. Activated carbon-based backfill is used as a filtering element. It helps to collect low concentrations of oil products and make the water suitable even for discharge into fishery facilities.

The next steps are:

For example, in the course of pilot tests at a metallurgical plant, specialists of BSG came up against the fact that the flotator and filters of additional water treatment were so contaminated with oil products that they did not purify water, but contaminated it repeatedly.

The sedimentation can be a preparatory stage before applying the other method, or it can follow it.

Coagulation can be strengthened by flocculation, then the process of combining suspended contaminants will go faster and larger flakes will form, which are easier to filter out.

Sorption is used when it is necessary to purify water to the stringent standards of maximum permissible concentration of petroleum products for discharge.

Sometimes the biological method of water purification from oil and petroleum products, but it is more related to the purification of oil sludge, but not sewage. The biological method of water treatment is the use of microorganisms that oxidize hydrocarbons. Because petroleum products negatively affect aerobic microorganisms, this method is not used in the process of cleaning water from petroleum products.

The choice of method depends on the composition of the flow, its volume, the required standards of maximum permissible concentration of petroleum products and the financial capabilities of the enterprise. To effectively treat oily wastewater, usually several methods are combined, which complement each other.

How oil ends up in water bodies

There are a number of situations where, through human error, petroleum contaminants-oil, fuel, cutting fluids (coolants) and other hydrocarbons-come into the water:- Accidental oil spills during its extraction, storage and especially transportation. 20% of spills that caused environmental disasters happened during transportation by pipelines and tankers.

- Wastewater of oil industrial enterprises. These are produced waters which appear during settling of the extracted oil, water after oil processing stages, water after washing equipment and reservoirs for oil products.

- Wastewater from industrial, metallurgical and machine-building enterprises, which use fuel and coolant to protect metal from oxidation, reduce friction and temperature during its processing.

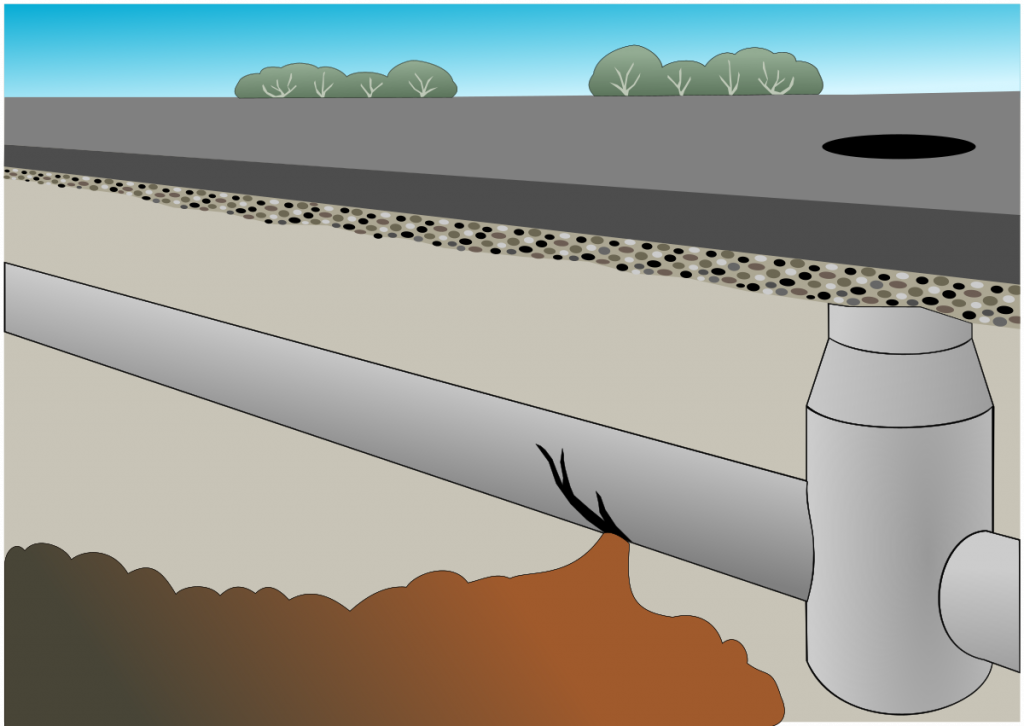

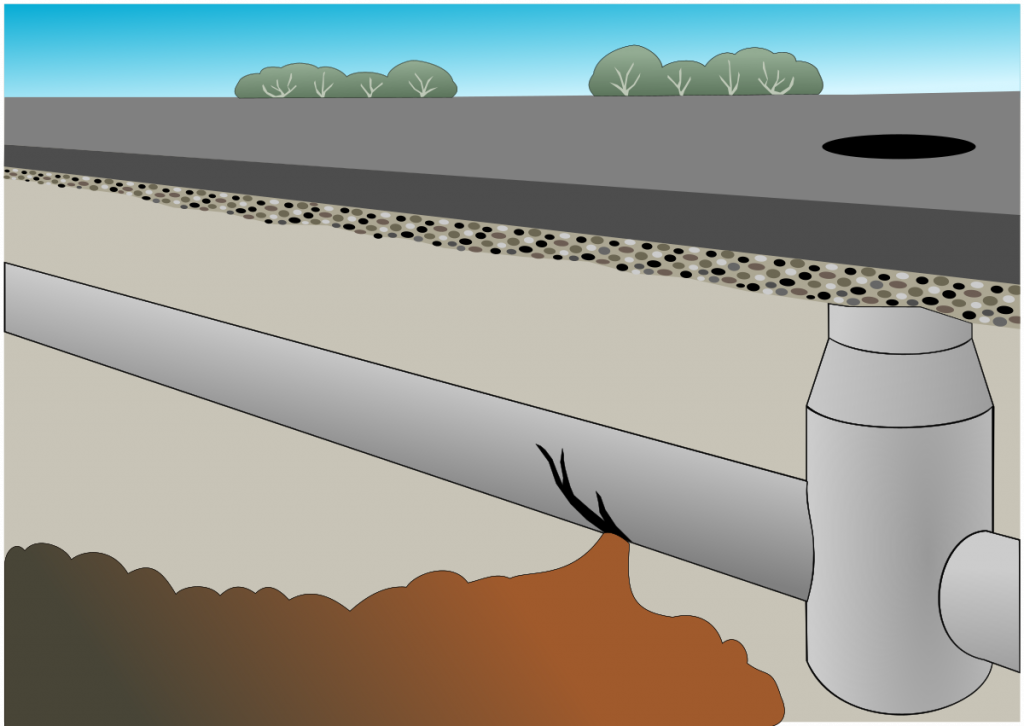

- Storm water with pollutants dissolved in it - various suspended substances, surfactants and petroleum products. This is precipitation that collected gasoline slicks, motor oil, and other fuel and lubricants from the roadway while it flowed into the rain sewer.

Oil-containing runoff can get into groundwater, and from there into wells

The Water Code of the Russian Federation forbids discharging untreated wastewater into bodies of water (part 6, article 60). Therefore, before that the wastewater goes through the sewage system, municipal treatment facilities or enters the sewage treatment facilities of the enterprise.After that, the content of petroleum products in water must not exceed MPC - the maximum allowable concentration norm, which guarantees that the water is safe for water inhabitants and people. For an enterprise, exceeding MPC in treated water or discharging untreated wastewater into a pond may result in higher environmental charges or fines. Let's take a look at the main ways to clean water from oily contaminants.

Ways to clean water from oil

Sedimentation

The liquid to be treated is pumped into a tank - settling tank or oil trap, where it stratifies: oil products float to the surface and relatively clean water remains underneath. Sedimentation lasts from 30 minutes to 24 hours.Some oil traps or oil traps have a coalescent filter - several polymeric plates placed close to each other. When runoff flows through them, the polymeric material attracts particles of oil-containing contaminants, where they are combined into droplets. The flow of water vibrates the plates and the droplets detach from them, float to the surface and form a film. This happens if the density of oily contaminants is less than the density of water. If the opposite is true, they settle to the bottom. The resulting film and sludge are collected and transferred for disposal.

Coalescence - convergence and coalescence of particles

Coagulation and flocculation

The coagulation method helps remove small particles of oily contaminants from the water, which do not settle and pass through the filter. Special reagents - coagulants bind such particles into flakes, which precipitate out. It can be removed by means of settling tanks, filters, flotation unit.

For a detailed description of how coagulants work, see the article "Coagulants: what they are and how they work".

Coagulation is supplemented by flocculation. This helps separate water from contaminants faster and form more large, dense flocs which are easier to remove.

Read more about flocculants in the article "Flocculants: what they are and how they differ from coagulants".

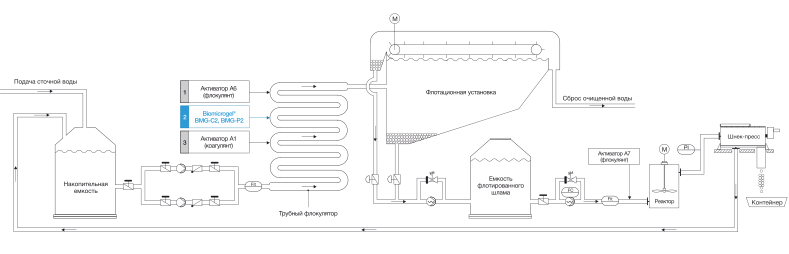

Flotation

This is the removal of contaminants from the fluid using flotation bubbles. When the effluent enters the flotation chamber, microbubbles are fed there. Contaminants stick to the bubbles and rise to the surface with them. From there they are collected by a scraper conveyor, discharged into a sludge collector, and the purified liquid is discharged from the flotation unit.

What flotators are and how they work - in the article "Flotator for wastewater treatment".

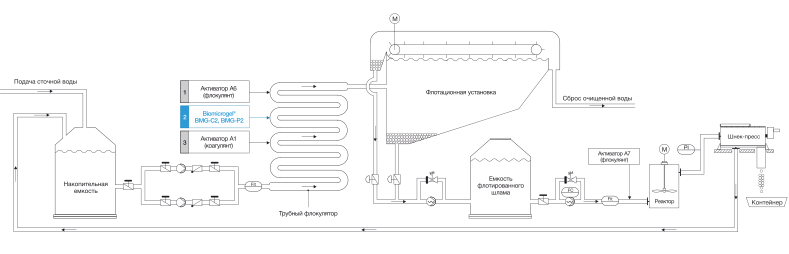

Scheme of oily wastewater treatment using flotator and reagents Biomicrogels®

Sorption

Sorption removal of petroleum products from water is the process of absorbing contaminants by sorbents. The type of sorbent material depends on where it is used. Sorbents in the form of powder or granules are used in water treatment, and fibrous ones - in production of filters, booms, oil-absorbing mats.This method is used when it is necessary to comply with stringent requirements for discharging effluents into water bodies, and other treatment methods do not give the desired result. For example, in the case of oily contaminants, water is sent for sorption filtration for further treatment. Activated carbon-based backfill is used as a filtering element. It helps to collect low concentrations of oil products and make the water suitable even for discharge into fishery facilities.

Choosing a method for cleaning wastewater from oil

To choose an effective treatment method, you need to analyze the effluent to determine what and how contaminated it is.The next steps are:

- Determining the volume of the effluent;

- Finding out what MPC standards the effluent must meet to be legally discharged to a treatment plant or to a water body;

- assessment of the financial capabilities of the enterprise.

According to Kommersant, large metallurgical companies are refusing to discharge wastewater into water bodies and are switching to a closed water cycle. Novolipetsk Steel has already converted more than 96% of its water consumption to recycling. Mikhailovsky mining and processing plant in Kursk region also plans to switch to recycled technical water supply.

Problems of cleaning wastewater from oil

It happens that the treatment scheme is correct, the wastewater goes through all the necessary stages, but the pollution in it exceeds the MPC standards. The main reasons are obsolete and/or worn-out equipment, improper selection of reagents and their dosage.For example, in the course of pilot tests at a metallurgical plant, specialists of BSG came up against the fact that the flotator and filters of additional water treatment were so contaminated with oil products that they did not purify water, but contaminated it repeatedly.

Replacing or repairing the equipment costs the company more than the EIA payments and fines from Rosprirodnadzor. For comparison: the cost of a flotation device for wastewater treatment is 730 000 rubles, and the fine for violation of water protection requirements is from 150 000 to 300 000 rubles for legal entities and from 50 000 to 80 000 for officials.

Conclusion

The effectiveness of water purification from oil products is important: if untreated effluent enters a water body, it leads to its waterlogging, shallowing, death of the inhabitants in it. There are several most common ways to clean water from oily contaminants: sedimentation, coagulation and flocculation, flotation, sorption. The last three methods belong to the physical and chemical ones.The sedimentation can be a preparatory stage before applying the other method, or it can follow it.

Coagulation can be strengthened by flocculation, then the process of combining suspended contaminants will go faster and larger flakes will form, which are easier to filter out.

Sorption is used when it is necessary to purify water to the stringent standards of maximum permissible concentration of petroleum products for discharge.

Sometimes the biological method of water purification from oil and petroleum products, but it is more related to the purification of oil sludge, but not sewage. The biological method of water treatment is the use of microorganisms that oxidize hydrocarbons. Because petroleum products negatively affect aerobic microorganisms, this method is not used in the process of cleaning water from petroleum products.

The choice of method depends on the composition of the flow, its volume, the required standards of maximum permissible concentration of petroleum products and the financial capabilities of the enterprise. To effectively treat oily wastewater, usually several methods are combined, which complement each other.

Other news

Need help? Send us a message and we’ll get back to you.

We process all enquiries and are able to find a customized solution for every client.

Cookies

We use cookies to optimize and continuously improve our website for individual users like you. Please consult our “Cookies policy” to learn more about how they are used on our website.